Dumper with exceptional performance and premium quality for demanding sites

HYPERMEC DUMPER

Our range of dumpers comes from the HyperMec philosophy focused on “custom-made” mechanical machining, where every stage of processing, from design to final testing, is carried out internally with craftsmanship by qualified professionals, using technologically advanced machinery and with the use of components from the best manufacturers.

Each HyperMec dumper is designed to give the customer a wide possibility of customization and to adapt to difficult working conditions, guaranteeing operator safety, reliability and productivity, thanks to performance superior to the generality of vehicles of the same type on the market.

Every HyperMec dumper is the safe investment in a reliable and long-lasting sort of co-worker.

QUALITY IS IN DETAILS

Each dumper is the result of the work and involvement of the entire HyperMec team and its partners.

An idea born in the years of study at the Polytechnic of Turin and KTH Royal Institute of Technology in Stockholm

This idea was first realized in a project with a high engineering content also

thanks to the contribution of strategic partners, and subsequently in a range of solid and well-built vehicles

in which emerges all the passion for mechanics and technical competence of HyperMec.

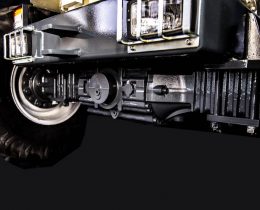

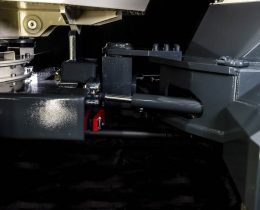

For the correct operation of the mechanics and to facilitate the replacement of wear components after years of use,

all components (including frames) are machined in the machine tool.

Each weld bead is sized to ensure mechanical tightness and is machined to obtain homogeneous surfaces.

Painting, in addition to its protective function, has an aesthetic value necessary to allow our customers

to create a prestigious image of your machinery and your company.

OUR PASSION IN EVERY DUMPER

Hypermec's craftsmanship know-how has developed a series of work vehicles with unique technical characteristics in the sector.

To describe what HyperMec means by quality and attention to detail, there is nothing better than a dialogue that took place some time ago between a HyperMec Contributor and a student visiting the company.

S: “Why are you taking so much care to remove every slightest burr as a result of machining in the machine tool?”

C: “Imagine if, driving a luxury car, you were injured due to a burr left on the steering wheel…”

S: “But here you build industrial products that should be handled with gloves”

C: “Even a luxury car should be driven with gloves on but, if you don’t wear them,

you don’t have to feel anything but the pleasure of quality!”